PSYCHOLOGICAL SAFETY:

THE BEDROCK OF HIGH-RELIABILITY OPERATIONS IN AIRCRAFT MAINTENANCE

Psychological safety is not a luxury but a necessity in aircraft maintenance units operating as High-Reliability Organizations (HROs). It empowers Aircraft Maintenance Technicians (AMTs) to report errors, share concerns, and contribute their expertise without fear of blame. Core HRO principles—such as preoccupation with failure and deference to expertise—rely on a culture of open communication. Without psychological safety, organizations risk silence, hidden errors, and systemic failures. By embracing a Just Culture that balances accountability with trust, aviation maintenance units can foster continuous learning, operational excellence, and true airworthiness.

In our previous article, we explored the foundational concept of psychological safety among Aircraft Maintenance Technicians (AMTs), defining it as a team’s shared belief in interpersonal risk-taking without negative consequences. We highlighted how this belief enables transparent reporting of errors and fosters collaboration, crucial elements in the safety-critical world of aviation maintenance. Building on that understanding, this piece delves into why psychological safety is not just beneficial, but an absolute necessity for organizations operating in the challenging framework of High-Reliability Organizations (HROs).

Aircraft Maintenance Units as High-Reliability Organizations (HROs)

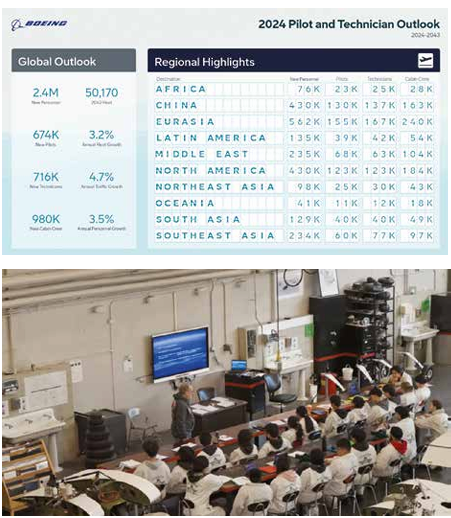

Aircraft maintenance units, whether in-house airline operations or independent Maintenance, Repair, and Overhaul (MRO) companies, function within the demanding environment of High-Reliability Organizations. HROs are entities that consistently achieve near error-free performance despite operating in hazardous conditions where the consequences of mistakes could be catastrophic. In aviation maintenance, where precision and collaboration are paramount for systemic reliability, the stakes are undeniably high. Human error, unfortunately, remains a significant contributing factor to aviation accidents, underscoring the critical need for robust safety mechanisms.

At the heart of the HRO philosophy are core principles designed to prevent catastrophic failures. Two prominent principles are “pre-occupation with failure” and “deference to expertise”.

Pre-occupation with failure means maintaining a constant “unease” and a continuous questioning of the status quo. Even minor indicators, anomalies, or near-misses are not dismissed but are actively used as opportunities to assess the system’s strength and condition. This encourages technicians to report potential issues without fear of reprisal, enabling swift corrective actions before they escalate into disasters.

Deference to expertise signifies that in safety-critical situations, the practical, tacit knowledge of frontline personnel is valued more highly than the theoretical expertise of those not directly involved in the operational process. This means that an AMT on the hangar floor, who possesses intimate knowledge of a specific aircraft system, should feel empowered to speak up, and their input should be prioritized and acted upon.

The Indispensable Role of Psychological Safety in HROs

Psychological safety is indispensable for HROs to genuinely achieve their safety objectives. It is the catalyst that cultivates an “informed culture” where open communication and information sharing between managers and employees are the norm. This openness allows organizations to identify risks promptly and proactively prevent accidents, a concept referred to as “organizational mindfulness”.

The inherent “unease” and “pre-occupation with failure” that characterize HROs make psychological safety an absolute necessity. Consider the perilous paradox: the very drive for perfection and a “zero accident” vision can inadvertently lead to the suppression of vital error reporting if psychological safety is absent. If employees fear negative consequences, such as blame, humiliation, or career damage, for highlighting potential problems or admitting errors, this fundamental HRO principle is directly undermined. This fear creates an “epidemic of silence,” where crucial information about systemic vulnerabilities or individual mistakes is withheld, preventing the organization from learning and adapting. Such concealment is far more dangerous than acknowledging and learning from incidents, as it allows latent errors to compound into catastrophic failures. Therefore, psychological safety serves as the critical link between the intent of HRO principles and their effective implementation, ensuring that the aspiration for perfection genuinely enhances safety rather than inadvertently fostering a dangerous suppression of safety-critical intelligence.

The “Just Culture” Connection

The concept of a “Just Culture” is closely intertwined with psychological safety in HROs. A Just Culture strives to balance psychological safety with accountability. It encourages employees to report safety-related information without fear of retribution for honest mistakes, while still addressing deliberate disregard for established procedures or reckless behavior. This distinction is vital: it promotes transparent reporting and continuous learning from unintentional errors, which are seen as opportunities for organizational improvement, while maintaining discipline and trust by holding individuals accountable for intentional violations. For AMTs, this means feeling safe to admit a missed inspection step or question an ambiguous protocol, knowing the focus will be on improving the system, not on assigning blame.

In conclusion, for aircraft maintenance units navigating increasing traffic volumes and technological complexity, psychological safety is not a “soft” ideal but a practical, strategic imperative. It transforms human fallibility into a proactive safety net, ensuring technicians prioritize airworthiness over silence. By fostering an environment where AMTs feel secure in speaking up, asking questions, and even admitting mistakes, organizations can truly achieve the continuous learning and nearly error-free performance demanded of High-Reliability Operations.